Modtec Brand Manual Briquette Machine in Utalii Manufacturing Equipment, Modtec Engineering

A briquette ( French: [bʁikɛt]; also spelled briquet) is a compressed block of coal dust [1] or other combustible biomass material (e.g. charcoal, sawdust, wood chips, [2] peat, or paper) used for fuel and kindling to start a fire. The term derives from the French word brique, meaning brick . Coal briquettes Lignite briquette Coal briquette

Professional Wood Charcoal Briquette Making Machine Buy Wood Briquette Machine,Charcoal

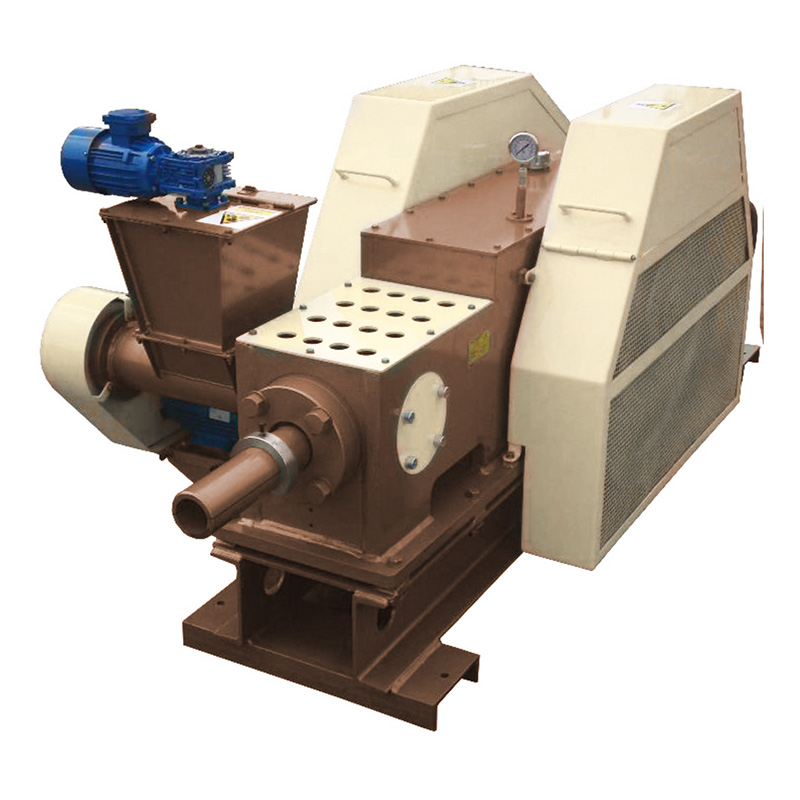

The Briquetting Machine aids in the binding of trash into complete briquettes, bio-coal, or white coal. The process involves pressing the raw material so hard that it becomes solidified with the help of the natural lignin found in the raw-material using briquetting press machines. A high-quality biomass briquette machine is required to produce.

UDB 2 dry crushing wood briquette making machine corn stalks briquette machinein Food

A briquetting machine, also called a briquette press machine or briquette-making machine, is a device that converts powdered or granular materials into larger, more convenient shapes called briquettes.. According to materials, there are 5 most popular briquette machines at present: charcoal briquette machine, coal briquette machine, metal powder briquette machine, lime briquette machine, and.

Hot Selling Small Charcoal Briquette Maker

Explore Machine TH 1500 Briquette press With matrix technology for industrial demands Explore Machine Series C Compact entry-level machines for small to medium throughputs Show all machines C 140 Briquette press Basic model for round 40 mm briquettes Explore Machine C 150 Briquette press

Coal Charcoal Ball Briquette Making Press Machine Price Buy Briquette Press,Charcoal Briquette

Industrial briquetting Customized solutions Compact design Easy integration into existing production lines HYDRAULIC BRIQUETTING machines Hydraulic Briquetting Systems can create briquettes from wood, biomass, metal and numerous other remnants. Capacities from 60 lb/hour to 2,600 lb/hour Quick installation Ideal for wood, metal, and biomass

charcoal bar making machine Coal Briquetter Machine

In summary, biomass briquette machines work by shredding organic materials, heating and softening the lignin, and compressing the biomass under high pressure to form briquettes. This innovative technology offers a sustainable solution for converting biomass waste into valuable fuel. Advantages of Using Biomass Briquetting Machine

Good Quality Hydraulic Press Briquette Machine For Coal Dust And Charcoal Buy Good Quality

Briquette machines increase available floor space. Convert scrap-storage space into revenue-producing manufacturing areas. We will work with you to provide a solution using very little space. Ten Metal Briquetting Machine Options for Your Manufacturing Operation

Charcoal Briquettes with 5 Types of Briquetting Machines (Budget Analysis) Fote Machinery

1 Put on old clothes and wear gloves. Making briquettes is an incredibly messy process. Before you begin, you should wear gloves to protect your hands and also put on old clothing. 2 Shred scrap papers into small pieces. Find scrap paper around your home. Old mail, flyers, and work papers work well. Shred them into tiny pieces. [1] 3

SemiAutomatic 5001000 kg/hr Briquette Mixing Machine And Briquette Making Machine, 10x20 And

Briquetting Machine Review About biomass briquettes. Making briquettes from biomass is a high efficient way to save your energy bill as well as to dispose of biomass waste. As a kind of renewable energy, the biomass briquettes, such as wood briquettes, saw dust briquettes or charcoal briquettes, made by briquetting machine, is widely used both.

Manufacturing Machines For Sale Page 2 of 8 Zhauns

RUF Briquetters use hydraulic pressure to create dense, high quality bricks out of metal, wood, and other biomass scrap. Create new revenue streams by selling briquettes for top dollar Save money by recycling and reusing raw materials Meet company sustainability goals Reclaim up to 97% of cutting fluids for reuse

Mechanical briquette machine Machines Aiding Environment MAE Development UK

Briquette-making machine parts. A pressing system, a heating system, and a cooling system are some of the vital parts of a briquette machine. To create a briquette, the raw material and binder must be compressed by the pressing mechanism. To speed up the bonding process, the mixture's temperature is increased using the heating system.

Buy UDMB 220 coal charcoal pressing machine briquette making machine from

Falach Briquette Machines are an excellent choice for productivity. The Falach 50 can produce up to 50kgs of briquettes per hour. Over the course of one week, 150 x 10kgs sacks of briquettes can be made and may sell for anywhere between £2.50-£3.00 per sack - a possible yearly income of over £12500!* (*based on 35-40 weeks of production).

fertilizer making machine How to choice high pressure briquette machine binder?

The machine was designed to compress biomass materials (sawdust, rice husk and palm fruit shell) in the briquetting die easily. The developed machine was fabricated using 100% local content. The.

The Applications of Briquette Machine's Final Product FTM Machinery

A briquette machine is used to turn the waste fine/powder into a regular shape block, which can help to improve the physical or chemical conditions for those powder, make it easy for transportation, storage, reduce the generated dust and be more useful for further applications.

High efficiency briquette machine for saleQingdao palet

Our briquetting machines can be used for many applications, where the best known are briquetting lines for consumer logs and industrial boilers. Lately, we have been delivering many lines for the production of briquettes from agricultural residues.

Amazing! Charcoal Briquettes Making Machine with a capacity of 500kg/h1000kg/h for the

Mechanical briquetting press is a pressing and forming machine for compressing the wood chips, sawdust, crop straws and forest residual into solid fuel with.